The Hidden Costs of Equipment Breakdowns: How Much Does It Cost to Fix and Replace a Flat Tire?

In agriculture, equipment downtime is more than just a temporary inconvenience—it can cost you time, money, and productivity. One of the most common yet underestimated issues? Flat tires. Whether it’s on a tractor, a baler, or a utility vehicle, a flat can bring your operation to a halt.

Understanding the full impact of a flat tire—and the broader implications of farm

equipment repair—is critical for today’s farmers, especially those running tight schedules and complex operations such as dairy farms. In this article, we’ll break down the cost of fixing and replacing a flat tire on your machinery, explore the ripple effects of unexpected breakdowns, and explain how regular maintenance can protect your bottom line.

Why Flat Tires Are a Big Deal on the Farm

Flat tires on farm equipment aren't just a nuisance—they’re a risk to productivity. In industries like dairy farming, where timing is everything, a single malfunction can affect the milking schedule, feed distribution, or critical harvesting operations.

Unlike your typical vehicle tire, farm machine tires are often specialized, larger, and more expensive. Replacing or repairing them requires more than a simple jack and wrench. That’s why having a plan for preventive maintenance and quick access to farm equipment repair services can make a major difference.

Average Cost to Fix a Flat on Farm Equipment

1. Basic Flat Repair

For minor punctures on utility vehicles or smaller tractors:

- Cost Range: $30–$80

- Includes: Patching, tube repair (if applicable), reinflation, and reinstallation

2. Tube Replacement

For older equipment or tires with internal tubes:

- Cost Range: $75–$150 (parts + labor)

- Tube tires are more common on vintage or smaller machines.

3. Tire Replacement

If the tire sidewall is damaged or the tread is worn beyond safe limits:

- Compact tractors or skid steers: $200–$400 per tire

- Mid-sized tractors or spreaders: $400–$700 per tire

- Large field equipment or combines: $800–$2,000+ per tire

Keep in mind that these prices can vary based on tire size, brand, load rating, and availability. Labor fees may also apply, especially if a service provider must travel to your location for an emergency repair.

Additional Costs to Consider

Fixing or replacing a flat tire involves more than just the tire itself. The hidden costs can add up quickly:

1. Downtime

Lost productivity during planting, milking, or harvest season can lead to major financial consequences. On a dairy farm, delays in feeding or milking can affect milk production and animal health.

2. Labor

While the machine is down, your employees may be idle or forced to improvise with alternative methods—both of which lower efficiency.

3. Transport Fees

If the equipment cannot be repaired on-site, hauling large machinery to a shop could cost hundreds in transport fees.

4. Missed Deadlines

If you're working under a tight schedule for harvesting, field prep, or livestock care, delays due to a breakdown can lead to cascading operational issues.

Farm Equipment Repair: Preventive vs. Emergency Service

Many farmers fall into the trap of waiting until equipment fails before calling a technician. But relying solely on emergency repairs often means higher costs, longer delays, and increased stress.

Emergency Repairs

- Typically cost 1.5x–2x more than scheduled service

- Limited availability during peak seasons

- Often reactive—addressing symptoms, not causes

Scheduled Farm Equipment Repair

- Allows for diagnostic checks and full inspections

- Reduces the risk of breakdowns during critical operations

- Enables you to plan for expenses and parts ordering

What Makes Dairy Farms Especially Vulnerable?

Dairy operations rely on a tight daily schedule. Milking systems, feed mixers, and transport vehicles must run like clockwork. Any disruption—like a flat tire on a feed wagon or transport ATV—can throw off your entire routine.

Cows need consistent milking and feeding times to maintain output. Delays caused by a broken-down machine can result in:

- Decreased milk production

- Increased animal stress

- Spoiled feed

- Loss of labor efficiency

Investing in reliable farm equipment repair and inspection services is essential for keeping dairy equipment and milking systems running smoothly.

Maintenance Tips to Avoid Flat Tire Costs

Prevention is always more affordable than repair. Here are a few steps farmers can take to avoid flat tires and unexpected repair bills:

1. Inspect Tires Regularly

Check for cracks, low pressure, or worn tread before each use. Early detection can prevent a blowout in the field.

2. Maintain Proper Inflation

Overinflated or underinflated tires are more likely to wear unevenly or fail under load. Use the correct PSI for each tire type and machine weight.

3. Use Ballast and Weight Distribution Wisely

Properly balanced loads prevent excessive strain on certain tires—especially on hilly terrain or uneven pastures.

4. Store Equipment Properly

Whenever possible, park machinery on a dry, level surface to prevent tires from degrading over time.

5. Partner with a Reliable Repair Provider

Find a local farm equipment repair company that understands the unique demands of agricultural equipment. Establishing a working relationship before emergencies arise ensures faster response times.

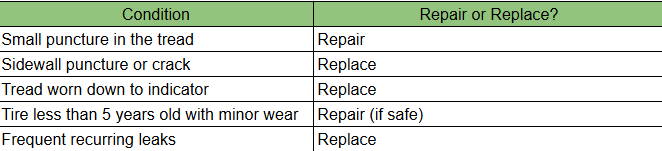

Repair or Replace? How to Decide

Sometimes it’s hard to know whether to repair or replace a damaged tire. Here’s a quick guide:

When in doubt, a professional technician should inspect the tire to determine the safest and most cost-effective option.

The Role of Technology in Modern Repairs

Today’s farm equipment repair services often use advanced tools to streamline diagnostics and maintenance. For example:

- Digital tire pressure gauges for fast and accurate readings

- Thermal imaging to detect uneven wear or internal tire damage

- Inventory tracking software to ensure tire availability during peak seasons

- Mobile repair units equipped to handle field-side emergencies

At C&C Farm Supply, we blend traditional know-how with modern equipment to deliver responsive, expert service that keeps your operation running smoothly.

How to Budget for Tire and Equipment Maintenance

Unexpected costs hit harder when there’s no room in the budget. Create a line item in your annual operating plan specifically for farm machine maintenance and tire replacement. You’ll be better prepared to act quickly when repairs are needed—and you’ll avoid sticker shock during the busy season.

Also consider enrolling in service programs or maintenance contracts offered by local suppliers. These plans often include regular inspections, discounts on parts, and priority service.

Final Thoughts: The True Cost of Neglecting Tire Repairs

Fixing or replacing a flat tire might seem like a small task—but the ripple effects of downtime, missed deadlines, and poor productivity can turn a minor issue into a major setback. When it comes to farm equipment repair, timely action saves money, reduces stress, and ensures your operation runs like the well-oiled machine it’s meant to be.

Don’t wait for a breakdown to stop your operation.

At C&C Farm Supply, we specialize in fast, reliable farm equipment repair for tractors, utility vehicles, dairy systems, and more. From flat tire service to full-system diagnostics, our team is here to keep your equipment in peak condition.

Call us today to schedule service or request emergency support. We’re here when you need us—on the farm, in the field, or at the barn.